Hydraulic Fittings

Timecon Instruments is an ISO 9001:2000 certified company based in Faridabad, Haryana in India. We are one of the leading manufacturer of various types of Hydraulic Fittings and allied products. We cater to the diverse needs of our customers with over 250 categories of hydraulic fittings. We also have our own R&D department that enables us to provide our clients with customized products as per their specific demands. Significant experience, incessant technology upgradation, approved quality management system facilitate us to offer pre-eminent covenant to all our customers.

Timecon Instruments prides itself in maintaining high quality standards for all its products and upholding customer satisfaction at all levels. Each of our product goes through a rigorous testing procedure before being cleared to be sent to client. The company has always believed in timely supply of the products at the most competitive prices earning ourselves a name in the industry. We believe in product innovations over time and thus our company keeps steadily extending its product range to cater to variable needs of our valued customers. With us, you have a reliable partner for your product needs regarding hydraulic fittings.

Technical Data and General Information

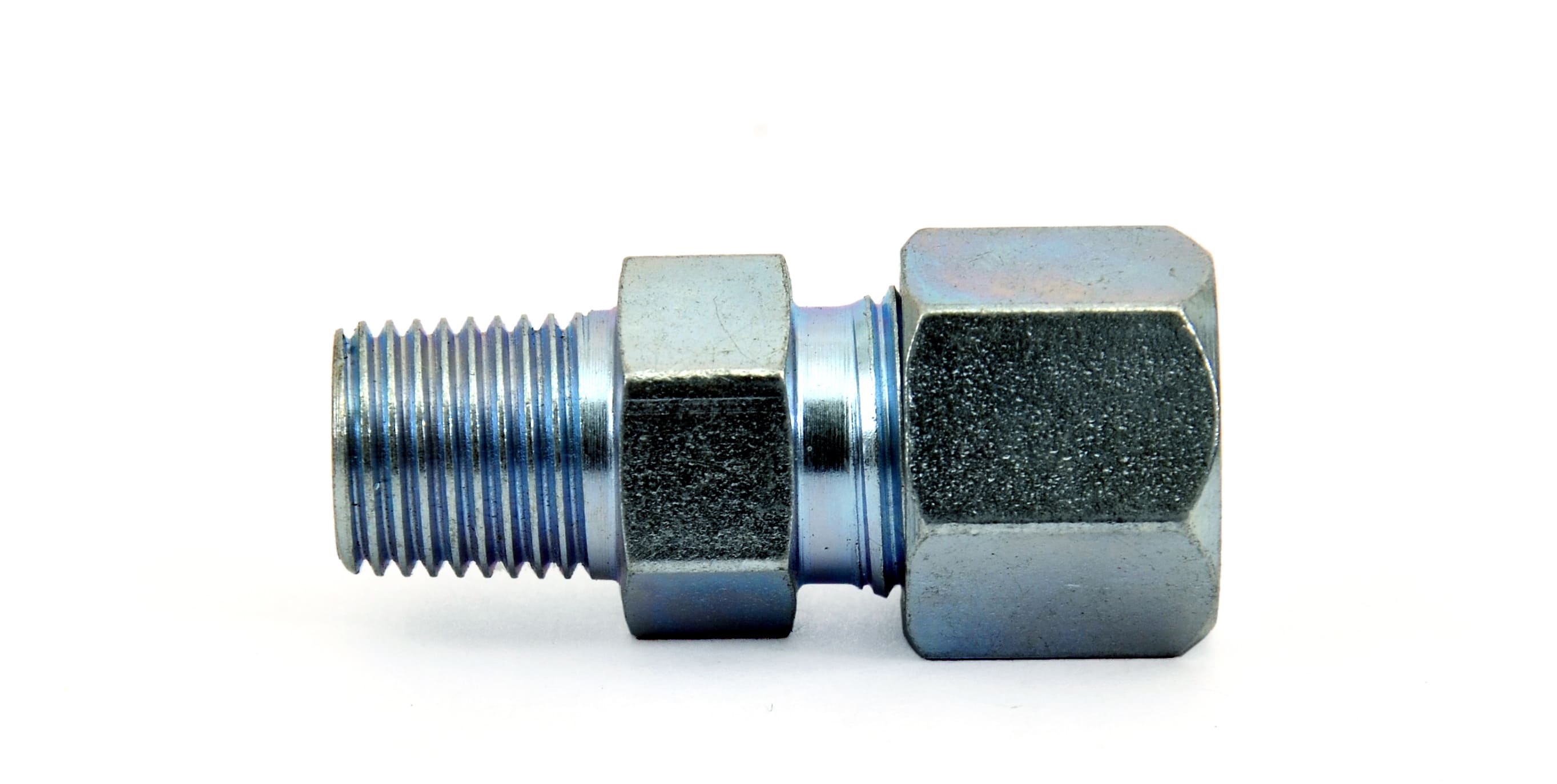

Working PrincipleTI Hydraulic Fittings are Flareless Bite Type fittings constituting three components namely socket body, progressive ring (ferrule) and coupling nut.

- Socket Body – These bodies are of various types such straight type, elbow, tee etc. The straight type fittings are manufactured from cold drawn steel bars whereas elbows and tee are forged and further machined as per requirement.

- Progressive Ring – Commonly known as ferrule, this component plays a major role in allowing a firm grip of the pipe in the fitting by making two 360 degree bite into the outside diameter of the pipe, thus ensuring an unusually high degree of safety and permanent sealing making the assembly leak proof. This proper biting of the progressive rings into the pipe is ensured by precision machining and heat treatment.

- Coupling Nut – The coupling nut are responsible for pushing the progressive ring onto the tube when tightened and ensuring a strong reliable connection. These nuts are manufactured from cold drawn material and are either cold or hot formed or machined to size as per requirements.